How 3D Printing is Changing the Health Care Landscape

Julie Bitely

| 3 min read

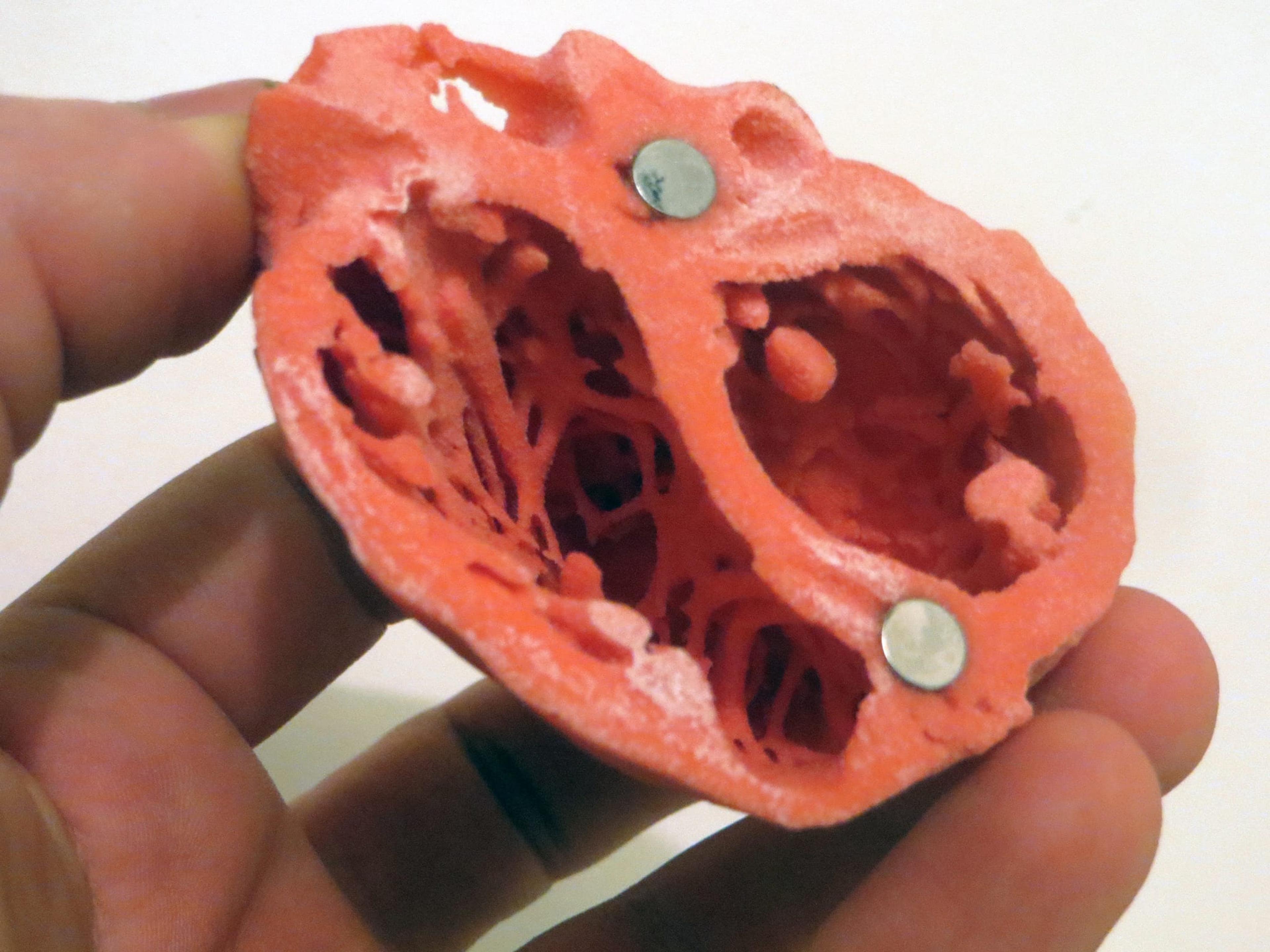

The future is now. Advances in health care move at a dizzying pace, but there’s something so futuristic about the field of additive fabrication, better known as 3D printing. While it’s not widespread yet, the technology’s use so far in heart surgery, prosthetic limbs, and even face transplants could revolutionize the way medicine is practiced. The promise it holds to save money, expand access to expensive treatments, and improve health outcomes is truly staggering. One researcher heavily enmeshed in the field is Roland Chen, a Research Investigator at the University of Michigan’s College of Engineering. He’s studying whether ankle-foot orthoses (AFO) created using 3D printing methods perform equally to orthoses made using traditional methods. His work in the field is made possible through a $75,000 grant from the Blue Cross Blue Shield of Michigan Foundation. AFOs are essentially braces used to modify the structural and functional characteristics of the foot and ankle. Patients might need a brace to correct or help treat gait problems stemming from a stroke, cerebral palsy, diabetes, obesity or other health conditions. Traditional AFOs are made by measuring the ankle and foot and making a negative plaster impression. A model is made, then fitted for the individual patient. The process can take up to two weeks and is quite labor intensive. Chen said 3D-printed versions can be made in a day so that it’s possible for patients to walk away with their AFO made in the same visit. There are certainly technical challenges to achieve that, but Chen and his research group believe it’s possible. While the traditional manufacturing model involves a certain level of artistry, 3D printing removes an element of human error, Chen explained. Plus, patients could save time and money by not having to endure repeated visits. Right now, Chen’s research has focused on himself and other healthy volunteers using the orthotic devices. He’s hopeful the project will prove that 3D models perform just as well as or even better than traditionally-made ones through evaluating how well the 3D versions correct. “In order to convince those who don’t want to try the new technology, you have to show them some very good results,” he said. Chen predicts 3D printing will not only help patients in need of AFO devices, but will eventually change the way medical students are taught basic and complex procedures. Right now, Chen said students often observe a procedure, then complete that procedure on a real patient before moving on to teach the procedure to complete their training. With 3D printing, he imagines a scenario that would include many rounds of practice on a model before moving on to performing procedures on an actual patient. Although this wouldn’t necessarily be a money-making way to put 3D printing to work, in theory it could save lives. Chen hopes that the industry will continue to scale up so that more and more medical facilities are able to use the technology in positive and life-changing applications. “It’s a fast-changing area,” Chen said. Check out this video to get a glimpse of how 3D printing works. The Blue Cross Blue Shield of Michigan Foundation supports research and programs to improve the health of Michigan residents. No grant money comes from the premium payments of Blue Cross Blue Shield of Michigan members. To learn more about BCBSM Foundation grant programs, visit bcbsm.com/foundation. Photo Credit: NIH Image Gallery